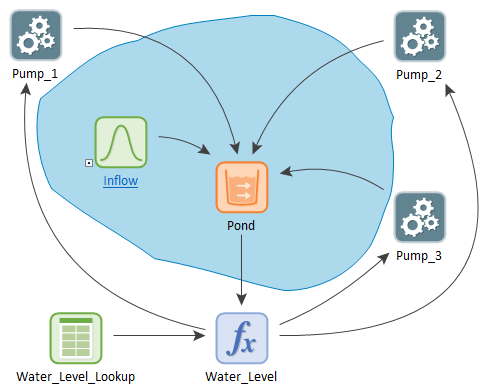

The model file Pond.gsm, found in the Reliability Examples folder in your GoldSim directory (accessed by selecting File | Open Example... from the main menu), is a simple model of a pond where the amount of water is controlled by three pumps. Water flows into the pond at a rate of 400m3/day, and it is pumped out of the pond by the three pumps.

In this model, we have a pond with an inflow rate of approximately 600 m3/day (the inflow is sampled daily from a Normal distribution with a mean of 600 m3/day and a SD of 100 m3/day).

Three pumps are used to remove this water. Each pump can only be operated if there is a sufficient depth of water in the pond (which varies from pump to pump). Pump_1 can only operate if there is more than 1.0m of water in the pond. Pump_2 can only operate if there is more than 2.0m of water in the pond. Pump_3 can only operate if there is more than 2.5m of water in the pond. The check to ensure sufficient water depth is done using a Condition type node in the External Requirements tree referencing the Water_Level element.

All three pumps can remove 300 m3/day and have an Exponential/Poisson failure mode with a failure rate of 1/3yr that is automatically repaired according to a Gamma distributed delay with a mean of 30 days and standard deviation The square root of the variance of a distribution. The variance is the second moment of the distribution and reflects the amount of spread or dispersion in the distribution. of 10 days. The calculation of the water removed from the pond by the pumps is done using a series of if/then/else statements referencing the condition of each pump. For example, the contribution of Pump_1 is calculated using the following if/then/else statement:

if (Pump_1 = RL_Operating, 300 m3/day, 0 m3/day)

The result of this statement is added to the result of similar statements for Pump_2 and Pump_3 to determine the Rate of Withdrawal from the Pond element.

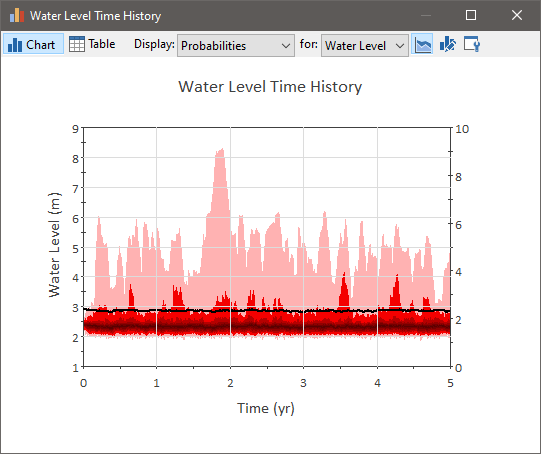

The time history of the water level in the pond over the course of the simulation looks like this:

The plot shows that for the most part, the level of the pond is controlled at about 2.4 meters. However, spikes as high as 8 meters can occur when the pumps fail.

- Example: Creating User-Defined Base Variables

- Example: Handling Actions Internally

- Example: Modeling Changing Operational Environments Using Failure Mode Acceleration

- Example: Modeling Component Maintenance and Replacement

- Example: Modeling Dependencies on Other Reliability Components

- Example: Modeling Dynamic Failure Mode Behavior Such as Burn-In

- Example: Modeling Non-Fatal Failure Modes

- Example: Modeling Resource Requirements for Reliability Elements

- Example: Modeling the Switchover to a Backup Component

- Example: Understanding the Differences Between Failure Mode Base Variables

- Example: Using Custom Reliability Outputs to Report Throughput Calculations

- Example: Using Reliability Elements for a Dam Risk Assessment

- Example: Using Reliability Elements to Model Failing Pumps

- Example: Using the Reliability Element's Primary Output

- Example: Working with Internal and External Requirements