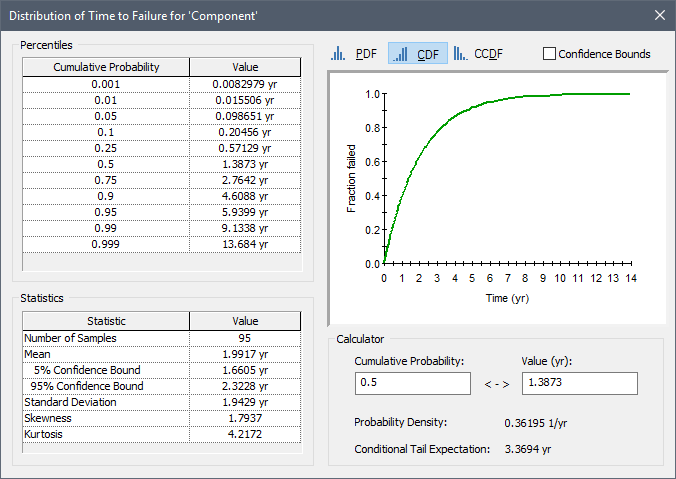

The Failure Times button in the Results tab of a reliability element allows you to view a distribution of the time to failure (from all modes) for the component:

Note: This dialog is nearly identical to the Distribution Summary for a standard Distribution result.

Note: The Display button for Failure Times is grayed out when the model is in Scenario Mode The state of a model when it contains scenario results, allowing multiple scenarios to be compared.. That is, you cannot view these results when running and comparing scenarios.

The Mean value that is displayed represents the Mean Time to Failure (MTTF) for the component.

The times to failure represent the time intervals between when the component starts operating to when it fails (i.e., the time to failure). Of course, if repairs are taking place, a single realization A single model run within a Monte Carlo simulation. It represents one possible path the system could follow through time. of the system can have multiple time intervals between failures. The distribution that is displayed incorporates all intervals for all realizations.

Note : If a component is being modeled as a system, a "failure" includes instances when the system fails directly and when it stops operating due to an internal requirement not being met. However, if it stops operating due to an external requirement not being met, this is not treated as a failure.

Ideally, a simulation will have produced a large number of failures and a well-defined distribution will have been developed by GoldSim. However, in some cases, the component will be unfailed at the end of the realization. This represents a censored sample of the failure time of the form "Failure time > X" , where X represents the time that the element had been operating as of the end of the realization. The manner in which this information is used to compute the failure distribution is described in Appendix A.

Note : GoldSim will only plot a failure distribution if there are at least 10 failure records (a failure record being either an actual failure time or a failure time of the form "Failure time > X"). In addition, at least 25% of the records must be an actual failure time (rather than a censored sample).

Learn more

- Availability and Reliability Histories and Statistics

- Availability and Reliability Results Summary

- Causal Analysis

- Defining and Using the Output Interface for a Reliability Element

- Exporting Availability and Reliability Summary Results

- Failure Times Statistics

- Reliability Element Status and Failure Mode Histories and Statistics

- Repair Times Statistics

- Saving and Accessing Reliability Results