GoldSim provides a number of reliability analysis tools that become available at the end of a simulation.

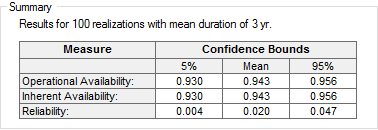

The most fundamental result is the summary of the mean reliability and availability The probability that a component or system is performing its required function at any given time. statistics over the duration of the simulation:

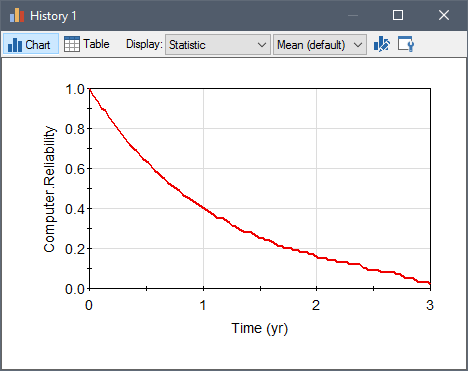

A wealth of additional information is also available. For example, a time history of the mean reliability can be displayed:

Also, statistical analyses of failure and repair time distributions can be displayed:

One of the most powerful types of result processing

available within the Reliability Module is

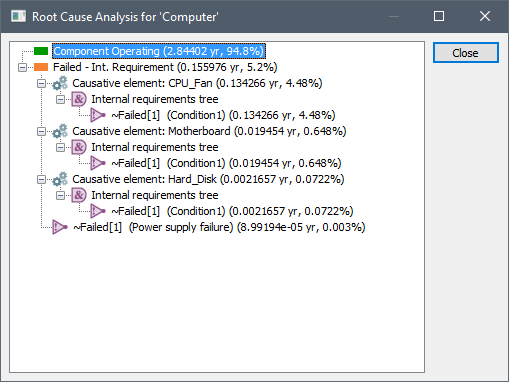

A related analysis shows the different failure scenarios for a system, where each scenario corresponds to a specific state of the system's components. Each state is presented as a logic-tree, with each component that is not operating shown highlighted (in red):

Once a model is built (in fact, while you are building it), it is critical that it is properly documented. This is discussed in the next

Learn more

- Adding Failure Modes to a Reliability Element

- Documenting Your Reliability Model

- Modeling Hierarchical Systems of Components

- Representing Logical Relationships Between Components

- The Reliability Elements

- Top-Down Modeling Using the Reliability Module

- Using GoldSim's Probabilistic Simulation Engine

- Viewing and Analyzing Results