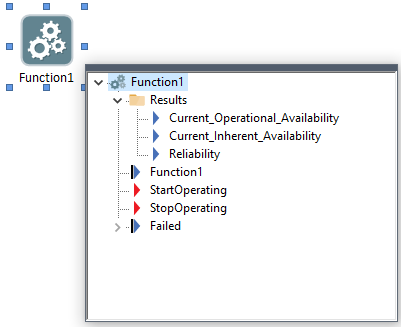

The Function and Action component share seven outputs:

Note that if the element is being modeled as a system with child elements, these outputs are contained within a "Properties" folder when viewing the output port for the element:

The Function and Action element's primary output For an element with multiple outputs, the output that has the same name as the element. (the output that takes on the same name as the element) is an integer that indicates the Status of the component. At any given time, it takes on one of the following values:

| Output Value | Component Status |

| 0 | All requirements are met, the component is not failed, it is turned on and operating. |

| 1 | A preventive maintenance (that makes the component inoperable) is underway. |

| 2 | Internal requirements (including failure modes) are not met. |

| 3 | External requirements are not met. |

| 4 | Element is not turned on. |

| 5 | Parent element is not operating. |

| 6 | An operating Resource Something that has a limited supply (e.g., spare parts, fuel, skilled personnel, money) and is required in order for elements of the modeled system to carry out certain actions. requirement is not met. |

If more than one status value applies at any given time, then the smallest value is output.

Because it is quite common to reference the status of a component, the Reliability Module provides some built-in constants to make it easier to read and recognize expressions that reference these values:

| Constant | Value |

| RL_Operating | 0 |

| RL_PM | 1 |

| RL_IntReqFail | 2 |

| RL_ExtReqFail | 3 |

| RL_Off | 4 |

| RL_ParentNotOp | 5 |

| RL_NotOpResources | 6 |

Hence, if you wanted to write an equation that checked whether or not the Function element "Computer" was operating, you could write either of the following conditional expressions:

Computer = 0; or

Computer = RL_Operating

Built-in constants can be entered directly, or can be inserted by selecting "Constants" from an input field's context menu (accessed by right-clicking in any input field).

Immediately below the Status output in the output port for a reliability element are found two discrete event signal A discrete signal indicating that something (e.g., an accident, an earthquake, a bank deposit) has occurred. outputs:

StartOperating: An event that is emitted when the element starts operating.

StopOperating: An event that is emitted when the element stops operating.

Below these two outputs you will also find the following output:

Failed: This is a vector A one-dimensional array.

of ten items. It is based on an array A collection of variables that share common output attributes and can be manipulated in GoldSim elements or input expressions. label set named FailureModes (with ten

items from 1 to 10) that is automatically provided by GoldSim. Each item in the

vector corresponds to a failure mode defined for the element (GoldSim allows up

to 10 failure modes). For example, Failed[1] corresponds to the failure

mode #1. Each item is set to True if its corresponding failure mode has occurred

(and it is reset to False if the mode is repaired).

By default, the Failed output is

not set to save time history results (since it is an array). To save time

history results for the Failed output, you must connect it to a Time History

Result element or right-click on it in the output interface and select the Save

Time History option.

Finally, within the output port for a reliability element there are three additional outputs provided in a folder named Results:

Current_Operational_Availability: This is the fraction of time the element was operating over a specified time period immediately previous to the current time. The specified time period is approximately 2% of the simulation duration.

Current_Inherent_Availability: This is the fraction of time the element was operable over a specified time period immediately previous to the current time. A component that is turned off or has unmet external requirements, but has not failed would be considered operable. Hence, the Inherent Availability The probability that the component will be operable at any given time (a component that is turned off or has unmet external requirements, but is not failed is considered to be operable). is always greater than or equal to the Operational Availability The probability that a component or system is performing its required function at any given time.. The specified time period is approximately 2% of the simulation duration.

Reliability: This value is 1 if the element has not failed, and 0 if it has failed. Unlike the availability results, no averaging period is required. At any point in time, the element has either failed or has not failed.

Note: These two availability results represent current (or, conceptually, instantaneous) values. They are different from and should not be confused with the availability results that are presented on the Results tab of Reliability elements, which represent the availability over the entire duration of the simulation.

Learn more

- Example: Using the Reliability Element's Primary Output

- Modeling Maintenance in the Reliability Module

- Modeling Resources in the Reliability Module

- Simulating Discrete Events

- Reliability Element Status and Failure Mode Histories and Statistics

- Availability and Reliability Histories and Statistics

- Availability and Reliability Results Summary

- Common Reliability Element Locally Available Properties

- Common Reliability Element Outputs

- Failure Rates and Failure Modes

- Features the Reliability Elements Share with All GoldSim Elements

- Modeling a Reliability Element as a System with Child Elements

- Operating Requirements

- Using Importance Sampling for Reliability Elements