In some cases, it may be appropriate to model a component as a system of sub-components. For example, you might want to model a computer as a system consisting of sub-components such as a power supply, a motherboard, a DVD drive, and a monitor. You could specify that in order for the computer to operate, the power supply, motherboard and monitor must all operate. You could further specify that the DVD drive could be inoperable without causing the computer to be inoperable.

You can turn a reliability element into a system by checking the Model this element as a system with child elements box. When you do so, there is a slight change in the appearance of the reliability element:

A small red triangle appears in the upper left-hand corner of the element, and clicking on the triangle takes you into a new layer of the model within the component. If you are familiar with GoldSim, you will recognize this plus sign as the same plus sign that normally appears on the GoldSim Container elements. In fact, when we convert a reliability element into a system, the element retains all of its properties, but now also functions as a (localized) Container.

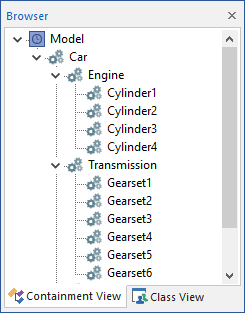

There is no limit to the degree of hierarchy you can build in this way. For example, a Car system might contain an Engine and a Transmission system. The Engine system within the car might have 4 Cylinder components, and the Transmission system 6 Gearset components:

When you build a system with sub-components, the parent (the system) and the children (the sub-components) can interact in three important ways:

•If the parent stops operating, the children immediately stop operating.

•If you specify any internal requirements for the parent (in the Operating Requirements portion of the dialog), these can act to stop the parent from operating based on whether or not the children are operating.

•For Action elements, the parent can delegate processing of its actions to its children.

Learn more about: